AEI FABRICATION

INSPECTION EQUIPMENT

LASER CUTTING – MILLING – FORMING

OUR KEYS TO PRECISION

BUILDING CONFIDENCES

AMADA FABRIVISION

LASER INSPECTION SYSTEM

FabriVISION Laser is a non-contact, flat part laser scanner that provides automatic measurement and digitizing capabilities that are an integral part of modern quality assurance models such as ISO 9000, TQM, SixSigma, and Lean. FabriVISION’s automated inspection processes will compare your first article to the original CAD drawings and generate a variety of color-coded reports that you can email directly to your customers. You will not only decrease your first article inspection time and increase your accuracy, but you can also use FabriVISION Laser to implement a continuous audit function in your manufacturing processes. FabriVISION Laser also allows you to reverse engineer flat parts directly into CAD files in minutes. The CAD files become your electronic template, which eliminates the need for maintaining a physical template. FabiVISION Laser will directly integrate with Amada’s AP100US with SDD and will also generate industry-standard CAD files.

SPECIFICATIONS

- SCANNING ACCURACY: ± 0.002” (0.05MM)

- MAXIMUM PART THICKNESS: 8.0” (200MM)

- MAXIMUM PART WEIGHT: 200LBS (90KG)

- CALIBRATION” AUTOMATED

- MAXIMUM SCAN ZONE: 48˝ X 48˝ (1220MM X 1220MM)

- HEIGHT MEASUREMENT : 3DI CAN MEASURE HEIGHTS UP TO 8

- OVERSIZED PART CAPACITY WITH AUTO ALIGNMENT ALLOWS PARTS OF UNLIMITED LENGTH TO BE SCANNED

- OVERALL DIMENSIONS: L79˝ X W65˝ X H100˝

- LASER : MAX OUTPUT 4.5 MW

RELIABLE HIGH PRECISION MANUFACTURING

At AEI Fabrication, we take pride in delivering exceptional results on high-precision projects, ensuring that every component is manufactured accurately to your specifications. With our expertise in both high-precision sheet metal manufacturing and intricate machining processes, we are well-equipped to handle your most demanding requirements. Our commitment to quality and consistency is further reinforced by our adherence to our ISO certifications, which serve as a testament to our rigorous quality management system. By working closely with our customers and meticulously following their specifications, we strive to provide tailored solutions that not only meet but exceed expectations, making AEI Fabrication your trusted partner for all your precision manufacturing needs.

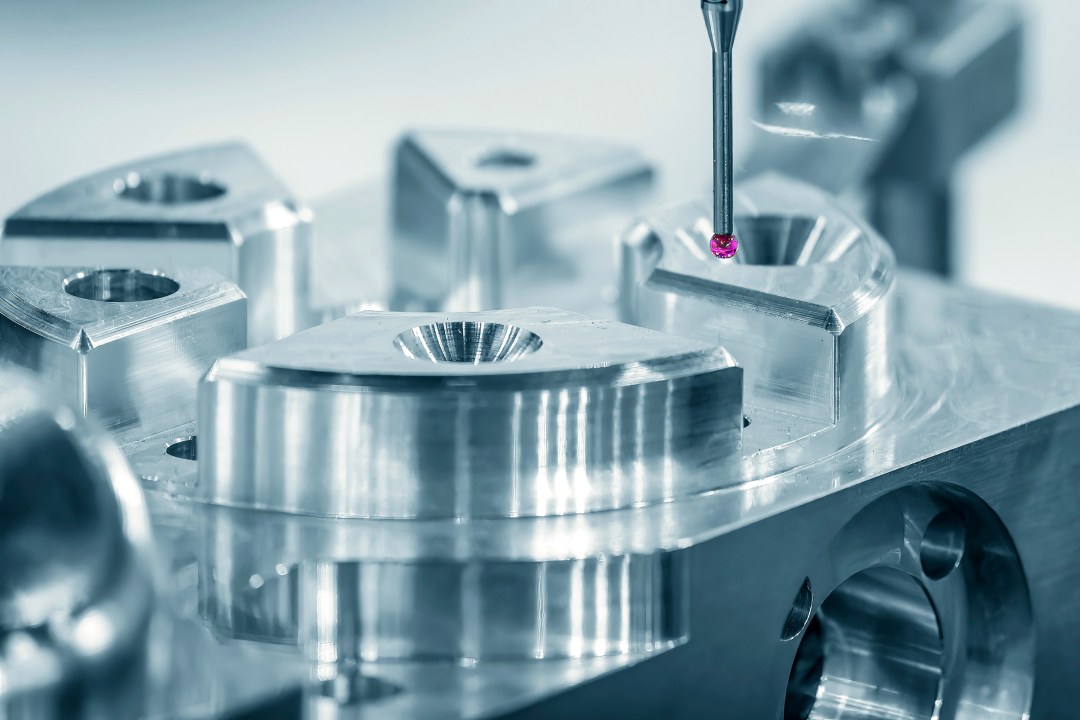

KEYENCE CMM XM Series

In our production process, we utilize the advanced KEYENCE CMM XM Series inspection tool to ensure the utmost accuracy and precision in our clients’ manufacturing projects. This state-of-the-art coordinate measuring machine enables us to perform rapid, non-contact measurements with remarkable precision, guaranteeing that each manufactured component adheres to the strictest tolerances and specifications. By integrating the KEYENCE CMM XM Series into our quality control processes, we can identify and rectify any potential discrepancies or deviations at the earliest stage, resulting in reduced lead times and enhanced customer satisfaction. Our clients can have complete confidence in the quality of their products, knowing that our commitment to excellence is backed by cutting-edge inspection technology.

SPECIFICATIONS

MEASURING RANGE

- 600mm×300mm×200mm (23.62”×11.81”×7.87”)

CAMERA

- Image pickup device: 4 megapixel CMOS image sensor

- Wavelength at light receiving center: Near-infrared

MINIMUM DISPLAY UNIT

- Distance: 1 µm

- Angle: 0.0001 degrees

MEASUREMENT ACCURACY & REPEATABILITY

- Stage locked: ±3 µm

- Stage unlocked: – ±4 µm

INDICATION ERROR

- Stage locked ±8 µm*1

- Stage unlocked – ± (10+L/100)µm*2

STAGE

- Withstand load: 25 kg

- X-axis movable range: – ±100mm ±3.94”

- Rotation range – ±60°

- Number of probes 1 or 2

- No. of markers – 6

- Marker light source: Near-infrared LED (870 nm)

WE ARE AEI FABRICATION

WE ARE A GROWING TEAM OF SKILLED INDIVIDUALS MANUFACTURING THE HIGHEST PRECISION PARTS IN THE INDUSTRY.

YOUR TRUSTED PARTNER IN MANUFACTURING

At AEI Fabrication, we specialize in cost-saving high-speed, precision laser cutting combined with efficient, full-service metal fabrication and machining, milling & turning capabilities to create a cost-effective, turn-key solution for clientele in a wide range of industry sectors.

Founded in 1995, we’ve been fabricating aluminum, steel and stainless industrial products and projects for over twenty years. We count many of the Fortune 2000 among our clientele, in industries including aerospace, bio-medical, semi conductor, warehousing, trucking, shipping, logistics, big-box retail, grocery, sports, alternative energy, entertainment, food service, manufacturing and education. We’re also proud to serve those that serve our country, with the U.S. Air Force and NASA among our family of valued clients. Our tenets of success start with a ‘can-do’ attitude fostered by our founder’s leadership that opens minds to possibilities and drives solution creation. AEI Fabrication is known industry-wide for working closely with clientele throughout the entire product development and production process to ensure the utmost in cost-efficiencies and customer satisfaction.

With our wide range of services from design to engineering to laser cutting to welding to machining to logistics, think of us as your ‘in-house’ fabricator. We maintain the tightest tolerances and guarantee meeting our clients deadlines. The key is putting our customer’s needs first by offering industry leading customer service.

THE START OF AEI

IN 1994 AEI BEGAN AS A LIGHTING COMPANY, DOING MAINLY ASSEMBLY AND OUTSOURCING METAL WORK. THROUGH THE YEARS AEI HAS EVOLVED INTO A HIGH PRECISION METAL PARTS MANUFACTURER PRODUCING ON AVERAGE MORE THAN 12,000 PARTS PER DAY